Nuclear industry

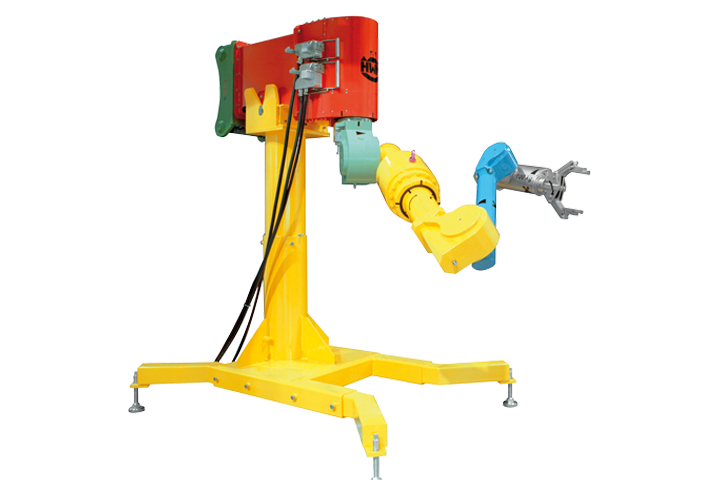

Skip navigationThe power pack among manipulators:

The A1000 for heavy tasks.

This is why the A1000 is the Number 1 manipulator

Arguments for the A1000 manipulator

What sets the A1000 apart:

- comfortable remote control

- efficient and diverse motion options

- radiation-resistant up to 1 MGy

- virtually maintenance-free

- electric drives in arm

- modular design

- external mechanical emergency drives for each joint (optional)

- possible to change arm elements remotely

- three different operating interfaces (control console, JOYARM and computer simulation) >

This wealth of compelling arguments makes the A1000 the best manipulator in radioactive and inaccessible environments.

Flexible and diverse usability thanks to modularity

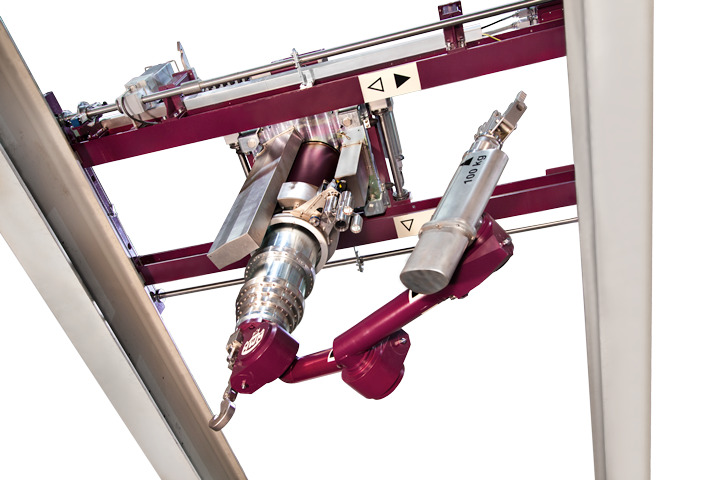

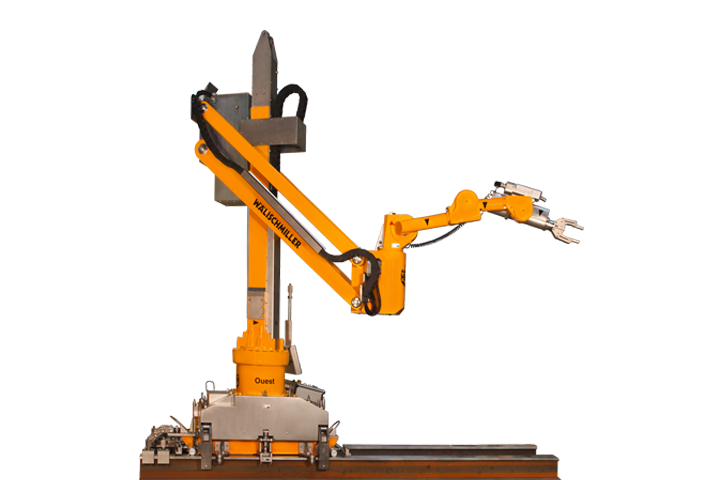

The A1000 is a modular power manipulator system for handling remote loads. You can use the manipulator anywhere: on a gantry crane, on the ground, on a vehicle (manipulator vehicle V1000), on an excavator or on a wall.

In its standard version, the A1000 manipulator consists of:

- a rail-dependent, movable bridge

- a carriage on the bridge

- a telescope with optional load hook to raise loads

- a manipulator arm

- as well as accessories such as tools

Result of the HWM engineering: infinitely easy handling

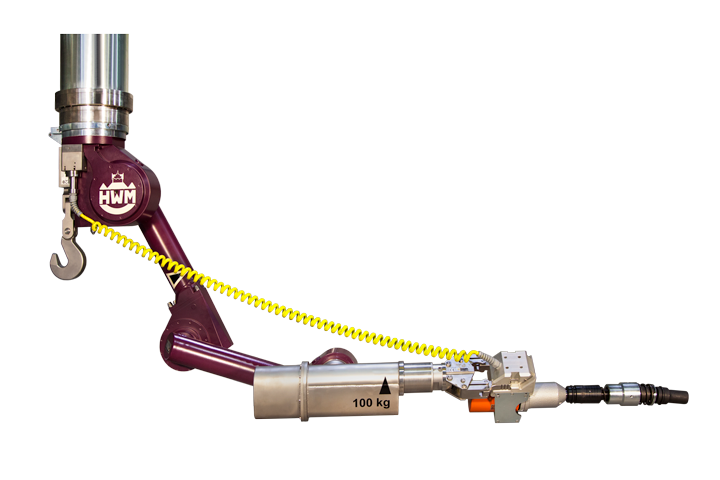

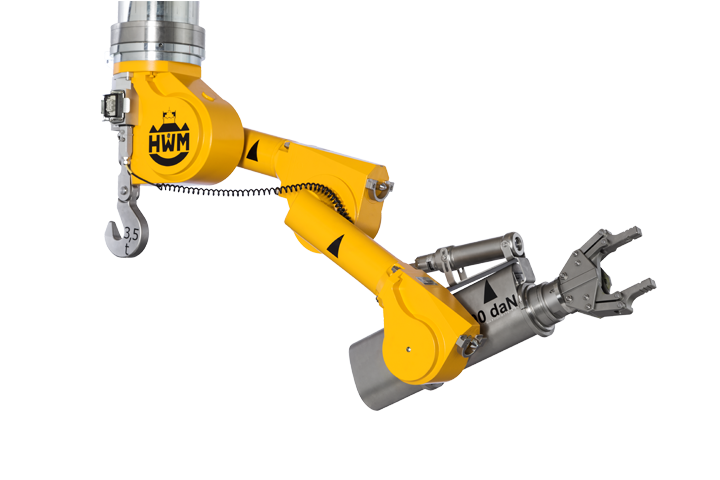

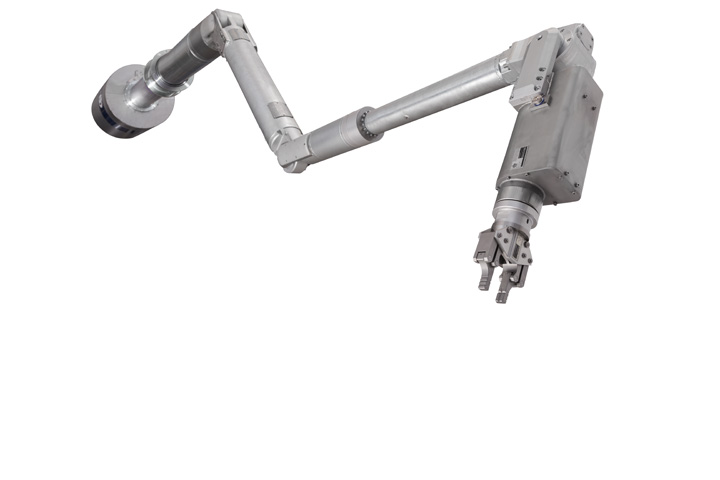

The manipulator arm has six electrically-driven axis which can be controlled remotely.

- Top arm swings (infinite rotary motion possible)

- Bottom arm swings (infinite rotary motion possible)

- Wrist swings (infinite rotary motion)

- Hand rotates (infinite rotary motion)

- Push with hand

- Tongs open and close

A particularly clever solution of the HWM engineers is behind the unlimited rotational movement of the various axes. This allows maximum flexibility in use. In addition to this, the optimised motion ranges ensure that every point in the prescribed working area can be reached.

Continuous motion with ergonomic, intuitive control

All motions are electrically driven. Motions are controlled via a PLC control system (standard) or if requested via a computer control system (see Type A1000S).

The speed and force of the motions are continuously adjustable. In combination with the ergonomic, transportable control console, the operator can operate the A1000 intuitively.

Maintenance-friendly to save time and expense

With the A1000, those constant maintenance jobs that you remember from other manufacturers are a thing of the past. Thanks to its special construction and optimisation to suit its field of application, the A1000 manipulator is particularly maintenance-friendly. For example, the internally-fitted cable is protected from damage and each arm section can be changed by simply loosening one screw.

Even decontamination is made considerably easier thanks to especially smooth surfaces and sealed components. You save time and money while the manipulator gains longevity and durability thanks to these refinements.

High quality materials for the strictest requirements

The A1000 is designed for a particularly long service life. Some A1000s have been in use for over thirty years. Years of experience and continuous development ensure the up-to-dateness of our products in the future as well.

The A1000 like all Wälischmiller products is subject to strict material and quality requirements. Learn more about it under „Products“! >

Individual enhancement options

The size and performance of the A1000 can be individually adapted to the specific requirements of your application. For example, components such as an auxiliary hoist or a complete robotic control system (A1000S and TELBOT®) can enormously expand the possible fields of application.

You can also find out about the Robot A1000S as well as the TELBOT®, and their extended applications. >

Case Studies

Power manipulator for wall installation

The electrical power manipulator A4000 is a manipulator with robotic functions for installation in a radiation protection wall in a 300 mm wall liner.